|

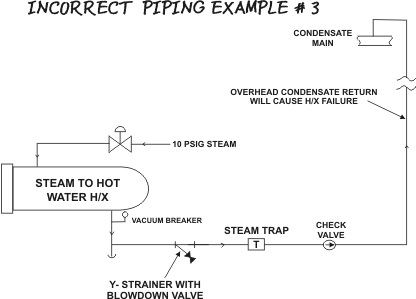

Failure Example # 3 |

|

Another example of poor design and faulty installation that I see very often are overhead condensate returns from steam coils and heat exchangers equipped with temperature control valves. An overhead condensate return is just that--the condensate line goes up and overhead instead of down when the condensate line leaves the steam trap. In such a situation, there is insufficient steam pressure to lift the condensate to the overhead return line. This happens during reduced load situations when the control valve is modulated or closed. The result is destructive water hammer leading to costly steam coil or heat exchanger replacement. |

|

Several years ago I visited the main equipment room of the beautiful new 68,000 Baltimore Ravens football stadium. There were at least 10 steam to hot water heat exchangers. Every one of them was piped incorrectly with an overhead condensate return, and every one of them was destined for premature failure and costly replacement. Remember, just because it's new and in an impressive building doesn't mean it's correct! |

||||

|

Failure example #1 (lack of vacuum breakers), failure example #2 (group trapping), and failure example #3 (overhead returns) are the most obvious of the 16 fundamental rules of good piping practice which I teach in my on-site training courses. The other 13 are just as important but are much less obvious

|

|||

© 2008 Steamtraining.com. All rights reserved. Terms of Use and Disclaimer |

||||||